China EPS moulding machine manufacturer

EPS moulding machine is to expand EPS raw material to required density, the machine works in a continuous way both in taking raw material and discharging expanded material.

EPS moulding machine can do second and third expansion to get low density.

Machine complete with Screw Conveyor, First and second expansion loader, Expander, Fluidized bed Drier

Application of EPS moulding machine

The fat barrel, outside an all-stainless steel compartment, has insulation measures, reliable performance, reasonable structure, beautiful, stable quality, high production efficiency, increase 2-3 times than the average machine, low energy consumption 25%.

The EPS moulding machine feed system including a feeding device and the second feeding device, a feeding device by adjusting the feed rate of transmission in order to ensure a stable feed.

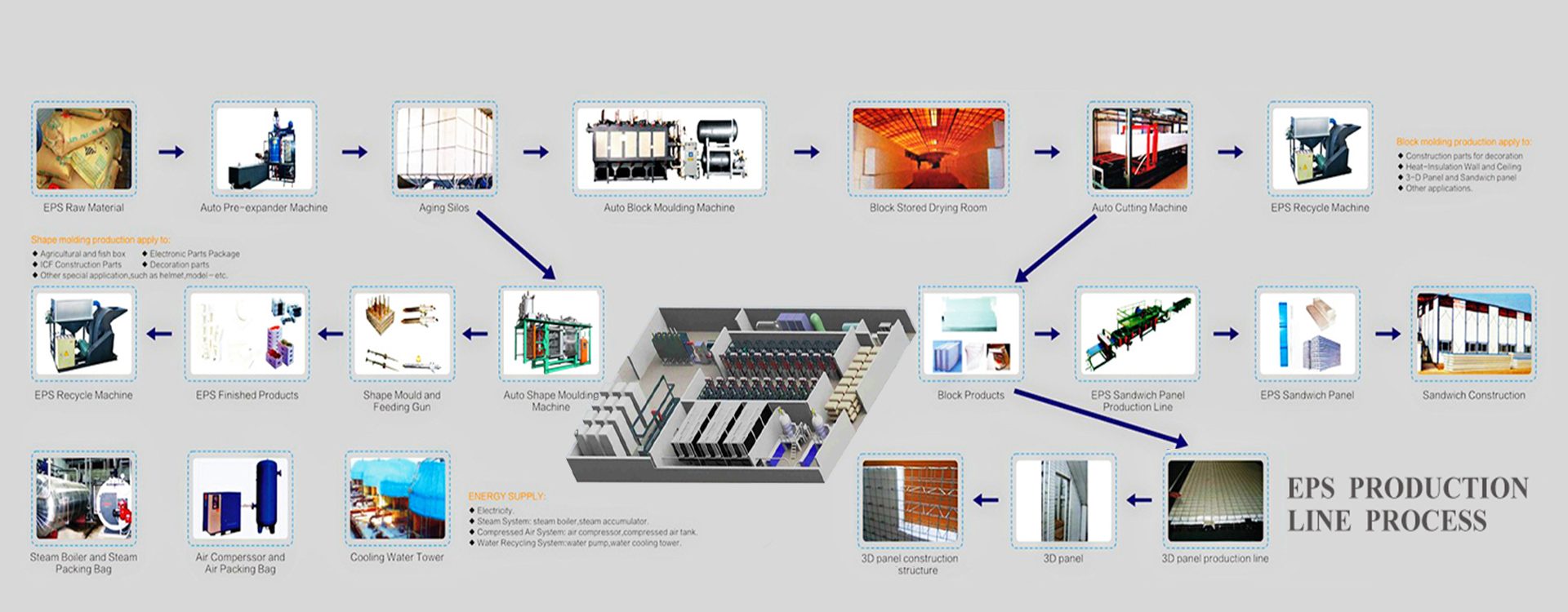

EPS beads through the material, the foam into the fluidized bed dryer ( customer optional ), and then into the aging silo through the fan delivery device, complete raw foaming process, process cycle according to the second foam.

The EPS moulding machine produced a more uniform density can foam density of 7-35kg/m3.

Let the steam valve, the user can choose according to need.

China Longwell EPS mold is a professional manufacturer of EPS moulding machine. The products are exported to dozens of countries and regions. Welcome more new and old customers to call or email for consultation.

What are the characteristics of EPS molds?

Many people don’t know much about EPS molds. In fact, in the ranks of foam packaging, EPS molds are one of the most commonly used molds. Professional molds can be customized to achieve the production of finished products. At present, there are many manufacturers in the market. EPS molds that can cast EPS occupies a relatively important position in industrial production. Many people are not very familiar with EPS molds. For this information, let’s talk about the characteristics of EPS molds.

Advantages of EPS mold:

EPS molds are relatively easy to demold, and most of its products on the market are processed with high-quality aluminum materials. Therefore, the owners of the products have the advantages of good toughness, resistance to deformation and light weight. Moreover, the design of aluminum materials is also used. It can ensure that the heating and cooling time on the production line is short, which is more convenient for customers to reduce their production costs, and at the same time can effectively improve their production efficiency.

Precautions for screening EPS molds:

EPS molds have relatively high precision requirements for quality. Therefore, when screening their molds, people should use the production process and quality of their molds as a measurement standard to check whether their process production has a sufficient level, which can also effectively reduce The loss rate of its molds can also provide a corresponding guarantee for its production efficiency.

The above is the introduction of the characteristics of EPS molds. For EPS molds, there are many professional manufacturers on the market today. Therefore, when customizing their molds, people should go through full market understanding and product comparison. It can ensure the selection of products with better quality assurance.

Excellent EPS mold supplier in China

Hangzhou Fuyang Longwell Industry Co., Ltd. We are EPS machinery supplier in Hangzhou, China, the manufacturing base of EPS machines. We offer kinds of EPS machines, EPS molds, 3D panel machines, sandwich panel machines, assistant facilities and all kinds of E P S machine spare parts.

We are specialized in E P S machinery design and turn-key project, and have helped many clients building E P S factories around the world, such as England, Italy, Cyprus, Greece, Ukraine, Russia, Australia, Turkey, Saudi Arabia, Qatar, Oman, U A E, Lebanon, Iraq, Jordan, Tunisia, Algeria, South Africa, Egypt, Mauritius, Vietnam, Thailand, Bangladesh, India, Sri Lanka, Pakistan, Uzbekistan, Tajikistan, Kazakhstan and etc.

So what are our advantages?

1. More years of industry experience

Due to lack of in-depth understanding, most of my friends do not know which part of choosing EPS mold supplier can get satisfactory results. In fact, as long as we have the patience to explore more things, we will soon know that manufacturers that have been established for many years, while focusing on the industry, have cooperated with different customers, and they will definitely have strong strength.

2. The surrounding transportation is convenient

Even if the EPS mold supplier can quickly stock up, the inconvenient transportation will affect the delivery efficiency, which is worthy of attention. The powerful manufacturers are located in a superior geographical location, and the logistics company can deliver faster and ensure on-time delivery.

3. Perfect after-sales service

Some EPS mold supplier are not able to deal with after-sales issues faster. Instead, they will find various excuses to avoid after-sales problems. Of course, this is not a trusted partner. Reliable manufacturers not only have a more complete service system, but also have more thoughtful and timely after-sales service, and can respond to customer feedback in the first time.

The soil for product survival is innovation, and the soil for enterprise survival is users. Hangzhou Fuyang Longwell has a high-quality after-sales service engineer team, which provides customers with one-stop service for after-sales product debugging and maintenance in a timely manner. We promise: all customer complaints will be responded within 24 hours.