China EPS moulding machine manufacturer, EPS Machine factory - Longwell EPS

China Longwell is a professional China EPS moulding machine manufacturer, EPS Machine factory. The products have passed strict quality certification and are exported to dozens of countries and regions in Europe and America.

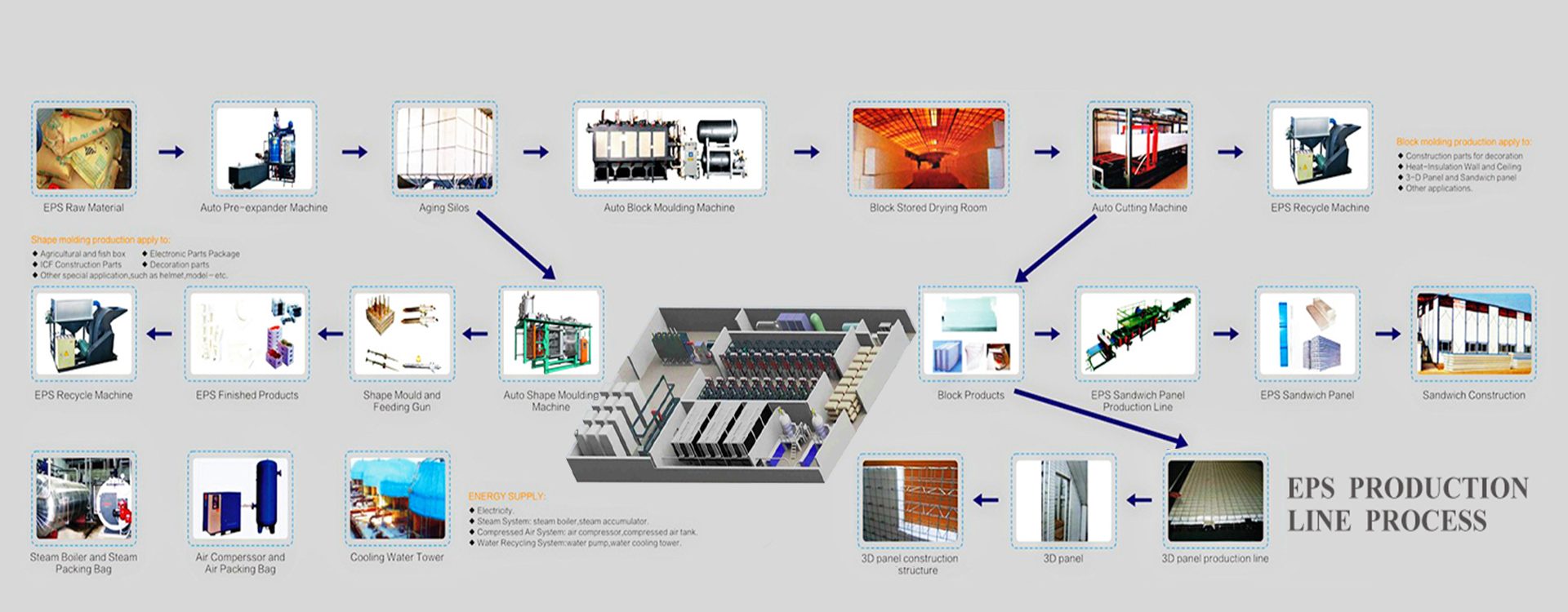

-1734925797545.jpg)

-1734932437947.jpeg)